메뉴Close

New next generation technology and the R&D infrastructure is our Changdae’s competiveness

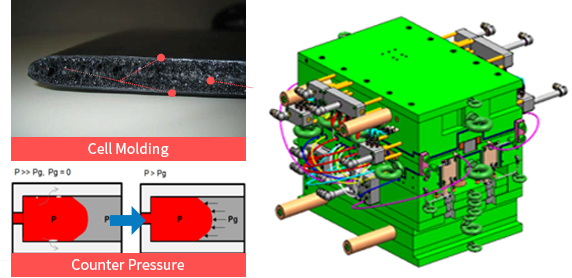

Cell Molding

Lighten plastic injection technology without bending and deformation

changdae

Cell Molding

Cell Molding

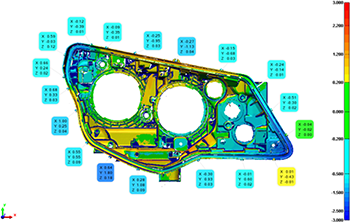

- Target: Automobile Lamp Housing lightening weight (20% down), no bending, deformation

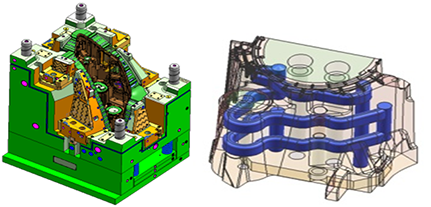

- 3D cooling mold design & process tech/ Equal heat & cool tech/ Dual Heat & Cool control tech/ automatic switchover control tech/ Auto Venting System tech/ Resin Rheology & mechanical evaluation/ optimizing Cell molding CAE/ optimizing injection process tech

-

-

Improved bending

Existing : 2.5~5.0mm

Improvement : 1.0~2.5mm

-

Weight saving

Existing : Standard weight

Existing : 20% Down ↓

-

3C Molding

Core Back + Counter Pressure + Cell Molding

changdae

Cell Molding

Cell Molding

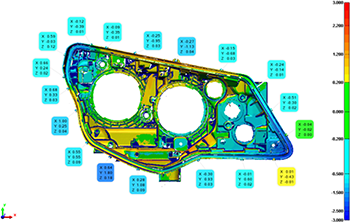

- Target : C/Stand, C/Rear : Lightweight (25%↓), zero bending, zero deformation, high-quality appearance

-

-

Cell MoldingHigh diffusion rate of supercritical fluid (SCF) Increased mobility of plastic molecules (30%↑ flow rate)

-

Core BackAfter the first injection molding is completed, the mold is core-backed with a certain pitch to complete the molding (lightweight)

-

Counter PressureMolding with internal pressure maintained at 40 Bar or higher (Air Pusher Controller)

-

Equal & Speed CoolingUniform heating, cooling 3D H&C structure mold design, processing and manufacturing

-